I’ve been working my way through fixing up vintage computers and software, so why not get a vintage tractor running?

TL;DR: good news: tractor runs, bad news, a lot of bad things

[photos: flickr – IH 484 tractor]

We inherited this 1979 International 484 from dad and it’s sat here a few years now. I slowly realized it’s no longer “that old tractor out in the field” but “my tractor” now, so I need to take care of it. Besides, the front end loader bucket would be super useful in cleaning the place up. I did not know what kind of condition it was in, if it actually “ran when parked” or not. I recalled there being some sort of problem with either the clutch or brakes. Dad had taken it to somebody to repair and they had either gave up trying to fix it or they sat on it for so long he gave up on them and went and brought it home.

I learned how to drive on this thing long before learning to driving a vehicle, I spent many summers raking hay and many cold winters putting out hay with it for the cattle. I wasn’t old enough to run the brush hog nor cut hay with it. I knew my way around but not in any serious maintenance capacity.

First thing first was seeing what kind of shape the battery was in and if the engine would even turn over. One trip I left a charger on it overnight, it was still dead and the best I could do was get some clicks and buzzes out of the starter. In the summer working on the electrical was a dangerous activity because of how many damned red wasps had nested inside it. At the very least I wanted to get the loader bucket off the ground as it was continually full of water and starting to rust, so I got a floor jack and got the bucket up on a concrete block to keep it drained.

The next trip I came back heavily prepared, I had found on eBay copies of the IH Blue Ribbon service manuals (I didn’t even know those existed prior), parts catalogs, and the operator’s manual. Normally I don’t like giving money to people who probably just printed a .PDF file, but I couldn’t find them otherwise and at the end of the day I still needed the manuals. At least they were nicely printed and bound bootleg copies. Ironically I’d like to have both .PDF and hard copy so I’m not hauling manuals back and forth to Oklahoma.

Theres a surprisingly scant amount of videos about this model on YouTube (other than for-sale videos) for how popular it was, yet old, I don’t know if I’m surprised or not. I at least found one video where somebody was trying to turn theirs by hand to check the starter and if the engine was seized up which gave me ideas what to expect checking mine.

Battery and a diesel mess

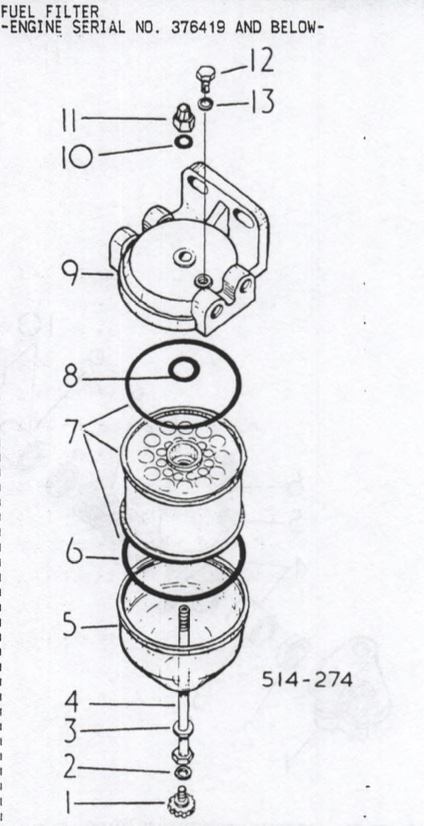

Next trip I went by Wal-mart and bought a new battery to stick in it. After putting it in I decided to try to check the filters for water. What I didn’t yet realize that whoever changed the filters last had tightened down on the drain screw to secure the new filter. When I thought I was loosening the bowl drain of the left filter, the entire filter assembly dropped off the head and diesel started pouring out of the line!

I couldn’t figure out how to get the damn filter re-attached, the bolt wasn’t screwing into anything. It took a good ten minutes if not longer for me to finally see that on top of the filter head was a loose nut that connects to the bolt that goes through the whole filter assembly. The front end loader frame obstructs the side of the tractor around the filters along with the fuel injector pump and I did not see this. It also made it quite difficult to get my hand in there to hold the nut in place while screwing the filter assembly back on. Meanwhile gallons of diesel had spilled out, which most certainly got rid of the water that I initially saw and then some.

This was all before I had fully digested the parts diagrams and manuals and probably could have avoided the mess. Looking at least one YouTube video, somebody else stumbled into this trap before I did.

To my surprise, and with a shot of ether starter fluid, the thing cranked over and actually started! It ran for several minutes just fine, no problems. The tires held air amazingly. The front end hydraulics, three-point hitch hydraulics all worked smoothly, forward and reverse gears worked, brakes worked, and I drove it around in small circles to try it out.

First startup

Test drive

First thing I figured out was there was indeed a problem with the transmission. I could not shift into high-range, with the clutch pedal depressed I was getting a quick grinding feeling that shouldn’t have been there. At least low-range gears 2-3 and reverse worked which is enough for moving around the place.

Previously talking to my BIL, he remembered the PTO wasn’t working, so I gave the brush hog a try. I’ve never used one before so what could go wrong. I figured out the second problem with the tractor, the PTO could be engaged, but it was very difficult to shut it off. It was like the lever couldn’t go back far enough to disengage, it had to be worked around and held back to finally disengage the PTO.

I made a couple of laps around the field with the brush hog. As I was coming back around the engine suddenly started choking and running rough, like I was running out of diesel yet I recalled there being around half a tank.

I parked and could not keep the the thing running for more than a couple of minutes every time. It was hard to start and was running very unevenly, like it was being choked of air or fuel. I actually wondered at one point if I had sucked a wasp nest into the air intake. I had the filter out while running, I was messing with the PTO when out of the corner of my eye I saw something swirling around inside the air canister that looked like a dirt dauber or wasp nest, and by the time I got things stopped it had disappeared. I don’t know if it fell out or got sucked in.

Rough idle – clogged diesel line?

Fuel dump

During the Christmas trip I decided to dump all the diesel and change the filters. This time I learned the fuel tank has a shutoff valve at the bottom and the manual actually says to shut that valve before changing the filter. Crankcase oil was a bit milky so it needed to be changed, and the radiator core was dry and needed about a half jug of coolant to top it off. I hooked up the air compressor and blew off a bunch of leaves and dust out of everything. I took a bunch of photos and measurements of things so I’d have reference later, particularly the electrical wiring behind the instrument panel.

I tried running my endoscope down the air intake to look for my wasp nest but had an annoying time seeing anything on my phone screen in the sun and getting the camera very deep. Judging by the diameter of the actual hole going into the intake manifold, it seems doubtful a wasp nest got in but who knows.

I tried to fix things up with the filters. I discovered I do indeed have the proper hollow bolt that goes through the filter for draining the water catch, I had feared the shady shade tree mechanic substituted their own part. I worked off the drain nuts that had been tightly screwed on, and cleaned out the inside so draining the bulb would work again like it should. For the life of me I couldn’t get the LH filter mounted again with the top o-ring installed, later looking at photos I saw the old o-ring at the top was still in the filter head. The LH filter had some rust stain which tells me it was sitting in water. A mirror would certainly be helpful for helping replace the O-rings and get the filter on.

The RH fuel filter was much easier to change as the front end loader frame didn’t get in the way nearly as much. Oddly I believe there was some slight differences between the RH and LH fuel bowls and packing rings, which again not sure if by design or shady mechanic. While I had it off I discovered that’s where the chassis(?) serial number plate was. I was beginning to believe it didn’t exist, it’s sure not where websites say it should be. Previously I was only aware of the serial number on the left side next to the clutch, which I believe is the engine serial number.

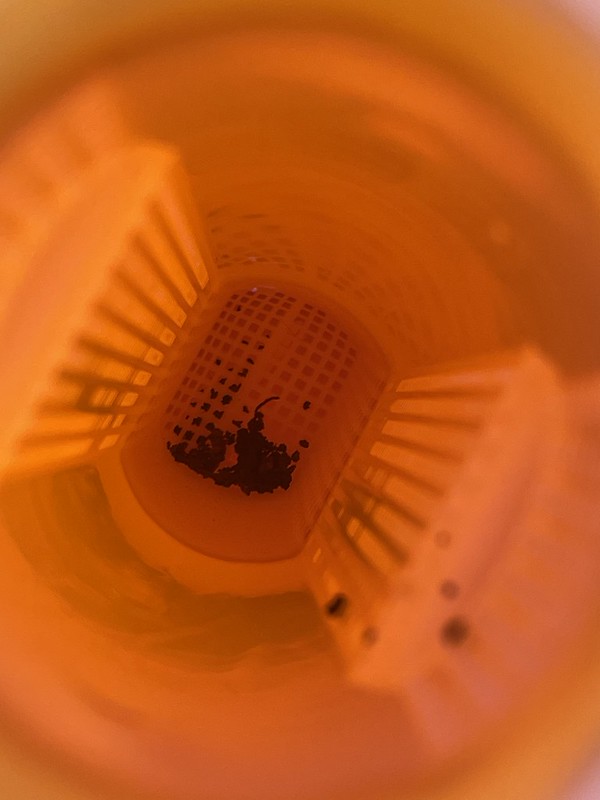

Interestingly while I had both filters out I had very little diesel running out compared to my first filter misadventure. This lead me to believe I had a blockage upstream somewhere which would explain why the engine was running so rough.

I unhooked the fuel line from the bottom of the fuel tank and diesel was just dripping out into my funnel, not a strong flow like I was expecting. I whacked the valve with a wrench and just like that what looked like coffee grinds started gushing out! I wanted to take the valve out to completely drain the tank but it seemed like it was in there pretty good so I left it be. I used compressed air to blow into the valve and tank a bit and blew the fuel line out while the filter was off, so pretty sure I got rid of all the rust and crap. If I had a longer transfer pump I’d try sucking out some of the nasty stuff at the bottom of the tank.

Unfortunately while trying to put everything back together, the nut on the end of the fuel line snapped in half.

Sigh.

The fuel line seems a lot longer than it needs to be so I think I can cut off the end, install a new nut, and re-flare the line. I didn’t have a flare tool so I didn’t do it this trip. I am moderately confident after getting this back together, getting air out of the lines, that the engine will run better next time. Before I left I did completely fill the tank with diesel to avoid any water condensation causing problems before I get back.

Helpful resources

I’m still figuring this all out. Getting the official parts catalog has been a huge help, absolutely worth the money I paid for it. It has tons of diagrams to show how things fit together, it lets me know what the names of parts are actually called rather than “the slidey rod through the hole”. I’ve quickly learned the parts numbers mean everything when trying to find replacements or look up anything online.

These YouTube channels had several IH 484 videos that I watched and gathered a lot from: